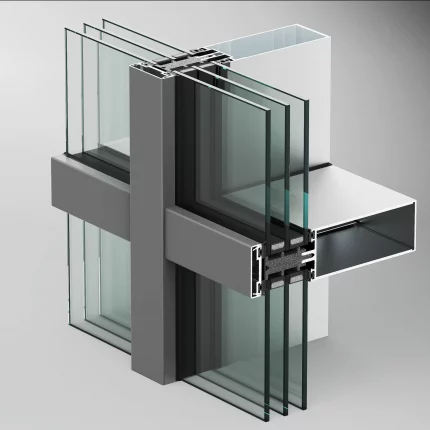

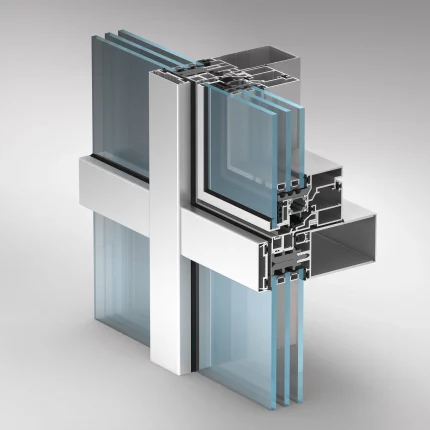

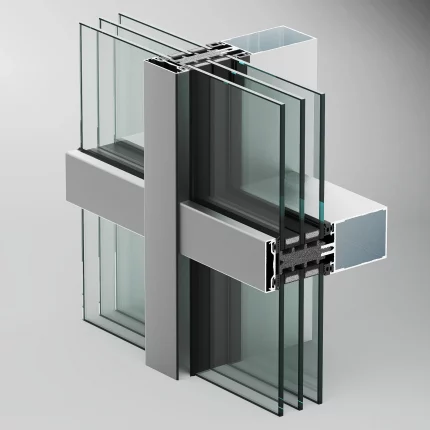

ALT EF65SG STRUCTURAL GLAZED UNITIZED CURTAIN WALL

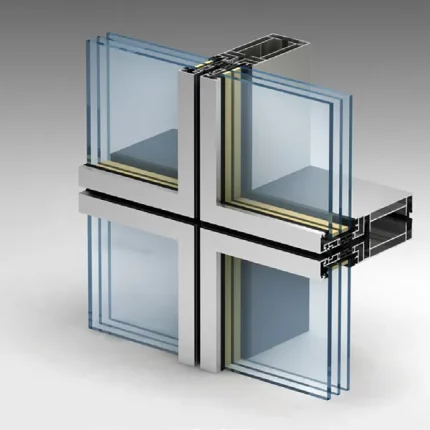

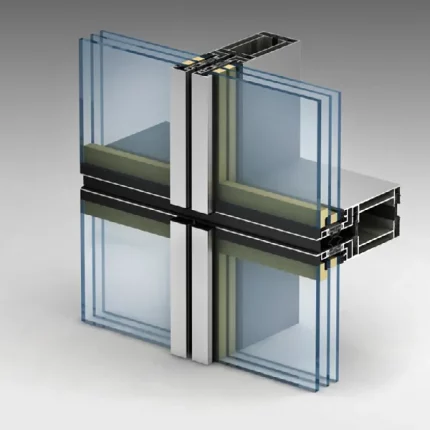

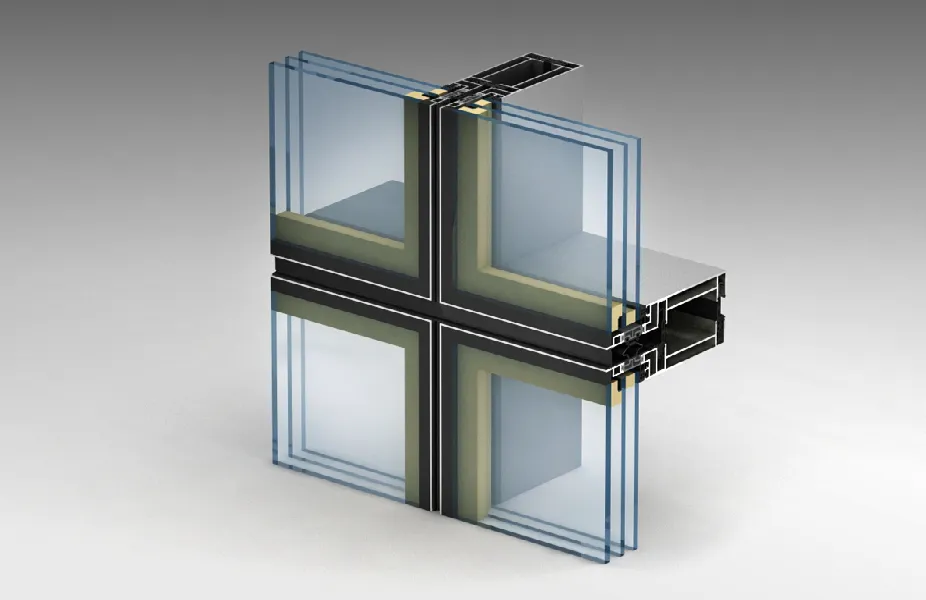

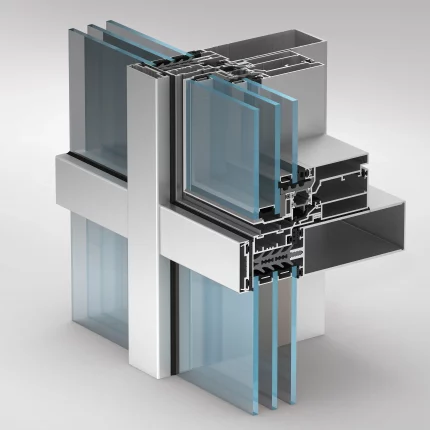

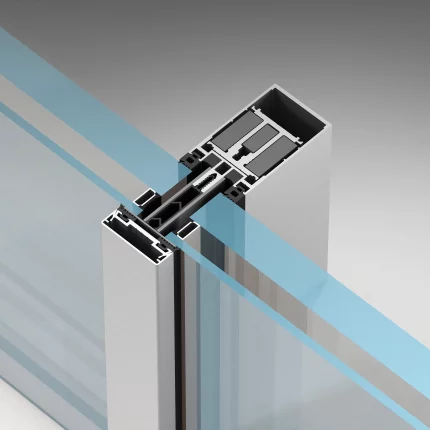

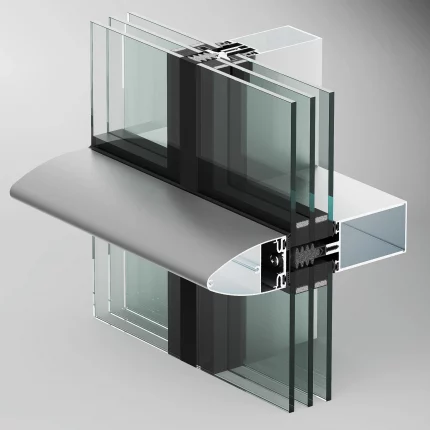

ALT EF65SG is a variant of modular facade system in which the infill unit is fixed from the end, therefore, giving the building facade the appearance of an all-glass surface.

For the element facade manufacturing with structural glazing, special double-glazed glass units are used, the outer chamber of which includes a U-shaped profile with glued double-sided adhesive tape AYPC.F50.1702 and a secondary structural sealant.

This system provides broad opportunities for architectural design while maintaining all the necessary indicators of tightness, strength and reliability, which are so necessary for high-rise buildings.

The design features of the element (modular) facade determine the high speed of work on the construction site, since all elements are completely pre-assembled in the workshop. At the same time, due to the small visible dimensions of the profiles (only 65 mm), high performance and technological efficiency are combined with architectural aesthetics.

| Max. infill unit thickness |

56 mm |

|---|---|

| Max. module height |

3600 mm |

| Max. sash width |

2700 mm |

| Max. infill unit weight |

500 kg |

| Thermal insulation EN ISO 10077-2:2017 |

Uf ≥ 0 , 8 W/м2∙K |

| Design |

Hidden sash , Unitized curtain walls |

| Energy |

High |

Fabrication benefits

- Standardization of elements at the stage of design.

- High assembly quality, precise control of manufacturing process, final quality inspection.

- On-site mounting with fewer work operations, which significantly reduces the «human factor» effect (faulty goods).

- Period of construction doesn’t depend on weather conditions, as the products are manufactured in the workshop.

- A floor-by-floor installation method is used, therefore, due to concealed thermal insulation jig finishing works can be carried out at the earlier stage.

- Mounting can be carried out at low temperatures without significant changes in the technological process.

1. POWDER COATING

- any RAL-colour according to Qualicoat;

- exclusive collections (Futura, Precis, Anodic);

- variety of surface types (glossy, matte, textured);

- innovative antimicrobial BIO-coating option.

2. ANODIZING

- conformance to Qualanod standard;

- 9 standard colours;

- possibility to choose different surface treatments (chemical etching, bead blasting, brushing).

3. WOOD-GRAIN EFFECT

- conformance to Qualicoat standard;

- 5 woodgrain options.